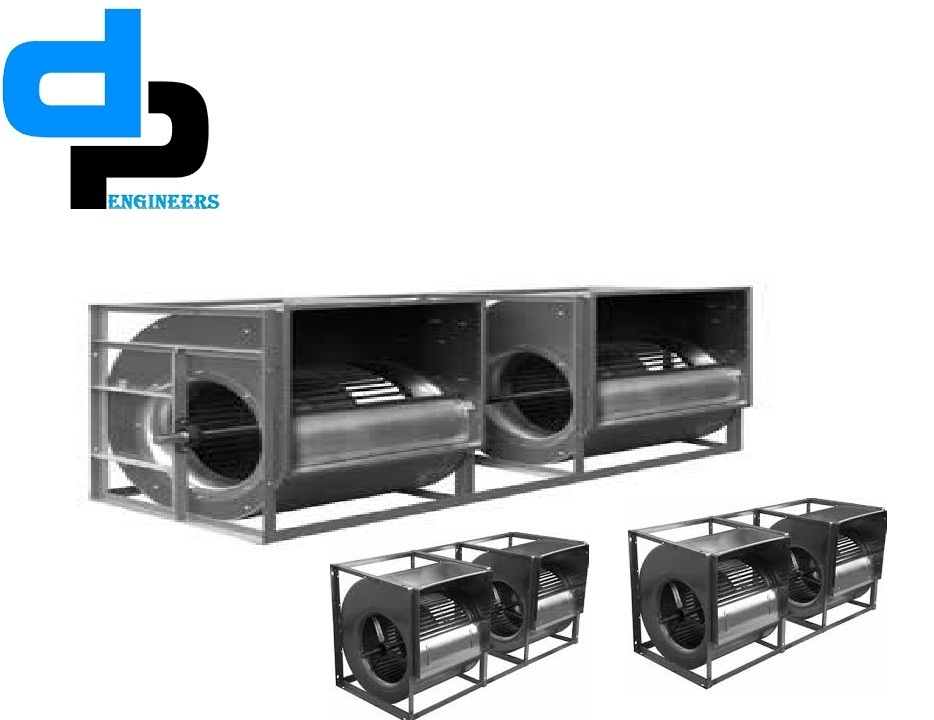

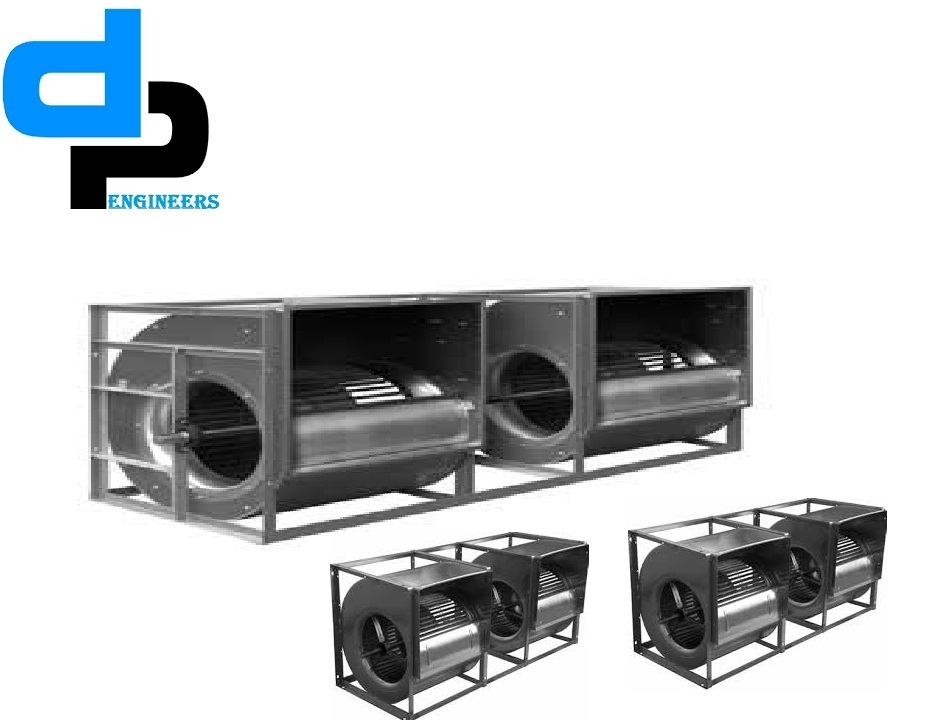

Nicotra Forward Curved Centrifugal Fan ADH 400 R

Nicotra Forward Curved Centrifugal Fan ADH 400 R Specification

- Motor Power

- 1.1 kW

- Power

- 1.1 kW

- Flow Rate

- 4200 m/h

- Pressure Range

- 350-470 Pa

- Life Span

- 10 years

- Max Pressure

- 470 Pa

- Output Power

- 1.1 kW

- Product Type

- Forward Curved Centrifugal Fan

- Material

- Galvanized Steel

- Capacity

- 4200 m/h

- Pressure

- 470 Pa

- Application

- HVAC, Ventilation, Air Handling Units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1400 RPM

- Noise Level

- <75 dB(A)

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- 54 kg

- Dimension (L*W*H)

- 645 mm x 855 mm x 715 mm

- Color

- Grey

Nicotra Forward Curved Centrifugal Fan ADH 400 R Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, South India, Central India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Haryana, North India, Chhattisgarh, All India

About Nicotra Forward Curved Centrifugal Fan ADH 400 R

Nicotra Forward Curved Centrifugal Fan ADH 400 R

Performance certified is for installation type B - free inlet, ducted outlet. Power rating (kW) does not include transmission losses. Performance ratings do not include the effects of appurtenances (accessories)

Nicotra Gebhardt S.p.A certifies that the fan shown herein is licensed to bear the AMCA Seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 211 and comply with the requirements of the AMCA Certified Ratings Program. The AMCA Certified Ratings Seal applies to air performance ratings only

ADH E and ADH G2E series

- Sizes 0160 up to 0560

- Scroll of galvanesed sheet steel with standing seam

- Straight cut off

- New cylindrical impeller with forward-curved blade geometry

- Galvanised shaft

- Pressure up to 2.200 Pa

ADH and ADH G2 Series

- Sizes 0630 up to 1000

- Lap jointed scroll of galvanized sheet steel with Pittsburgh-Seam and V-cut off

- Pressure up to 1.800 Pa

Efficient Airflow for Demanding Applications

The Nicotra ADH 400 R Forward Curved Centrifugal Fan is tailored for environments that require precise and substantial air movement, such as HVAC systems, air handling units, and ventilation projects. Offering a flow rate of 4200 m/h and pressure up to 470 Pa, this solution meets the needs of both industrial and commercial settings with stable and reliable airflow.

Engineered for Low Maintenance and Durability

Built with galvanized steel impellers and sealed ball bearings, the ADH 400 R is designed for longevity and minimal upkeep. The motors Class F insulation and IP54 enclosure ensure safe, continuous performance in harsh conditions, while its maintenance-free design reduces operational costs over its impressive 10-year lifespan.

Flexible Installation and Reliable Performance

With a compact footprint and floor or platform mounting options, the Nicotra fan offers installation flexibility for tight mechanical spaces. Operating on 415 V, 50 Hz, and delivering robust output power of 1.1 kW with a sound level below 75 dB(A), it ensures both efficiency and quiet operation in any facility.

FAQs of Nicotra Forward Curved Centrifugal Fan ADH 400 R:

Q: How is the Nicotra Forward Curved Centrifugal Fan ADH 400 R typically installed?

A: The ADH 400 R is designed for floor or platform mounting, ensuring stability and ease of integration into HVAC systems, air handling units, or ventilation setups in commercial and industrial spaces.Q: What materials are used in the construction of this fan and what benefits do they offer?

A: The frame is made of durable sheet steel, while the impeller features galvanized steel. These materials provide excellent resistance against corrosion, extending the fans lifespan and maintaining high performance in challenging operating conditions.Q: When is this fan the most suitable choice for an application?

A: This model is ideal for applications that require high airflow and moderate pressure, such as HVAC systems, air handling units, and ventilation in buildings or industrial facilities. Its robust construction and maintenance-free operation make it perfect for continuous-duty scenarios.Q: Where can the fan be used, and what are its typical applications?

A: The fan caters to HVAC, air handling units, and various ventilation systems across commercial buildings, manufacturing facilities, and industrial premises. Its noise level below 75 dB(A) makes it a good fit for places where quiet operation is necessary.Q: What is the maximum operating temperature range for the ADH 400 R?

A: The fan operates efficiently in ambient temperatures ranging from -20C to +60C, allowing it to function reliably in both cold and warm environments.Q: How does the belt-driven mechanism enhance the performance of this fan?

A: The belt-driven design allows the impeller to operate at optimal speeds, reducing motor wear and enabling flexibility in fan speed adjustment, resulting in tailored airflow and quieter operation.Q: What maintenance is required for optimal fan performance?

A: Thanks to its sealed ball bearings and maintenance-free design, the ADH 400 R requires minimal maintenance, lowering overall operating costs and ensuring long-term reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ADH Nicotra Forward Curved Centrifugal Fan Category

Nicotra Forward Curved Centrifugal Fan ADH 225 R

Price 17000 INR

Minimum Order Quantity : 2 Pieces

Motor Speed : 1400 RPM

Max Pressure : 600 Pa

Voltage : 230/415 V

Capacity : 1900 m/h

Nicotra Forward Curved Centrifugal Fan ADH 800 K

Price 110600.00 INR

Minimum Order Quantity : 1 Piece

Motor Speed : 960 RPM

Max Pressure : 780 Pa

Voltage : 415 V

Capacity : Up to 19600 m/h

Nicotra Forward Curved Centrifugal Fan ADH 200 R

Price 16500 INR

Minimum Order Quantity : 2 Pieces

Motor Speed : 2850 RPM

Max Pressure : 500 Pa

Voltage : 220240 V

Capacity : 900 m/h

Nicotra Forward Curved Centrifugal Fan ADH 630 R

Price 62000.00 INR

Minimum Order Quantity : 1 Piece

Motor Speed : 1440 rpm

Max Pressure : 800 Pa

Voltage : 415 V

Capacity : Up to 9000 m/h

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS