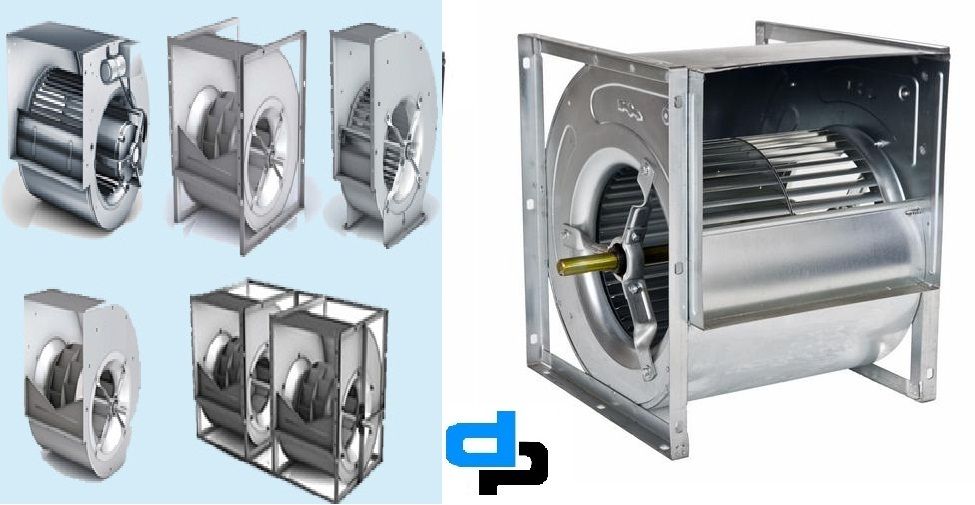

Nicotra Forward Curved Centrifugal Fan ADH 1400 X1

Nicotra Forward Curved Centrifugal Fan ADH 1400 X1 Specification

- Pressure Range

- 300 - 720 Pa

- Flow Rate

- Up to 37000 m/h

- Max Pressure

- 720 Pa

- Output Power

- 7.5 kW

- Power

- 7.5 kW

- Life Span

- Over 10 Years (on proper maintenance)

- Motor Power

- 7.5 kW

- Product Type

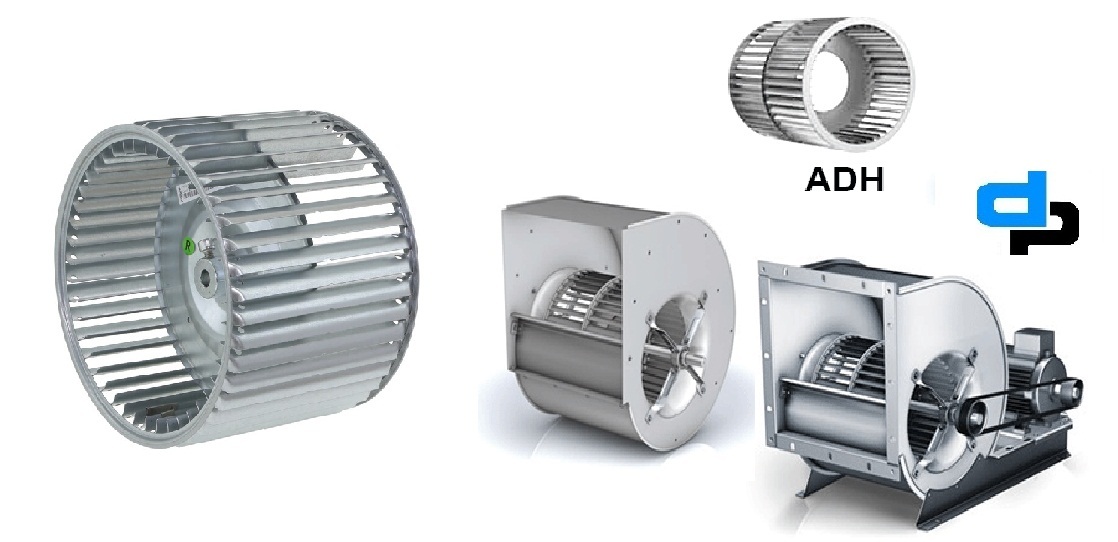

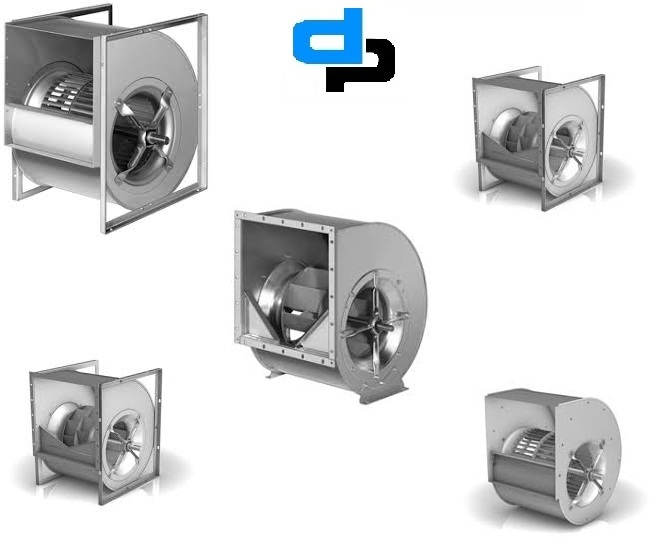

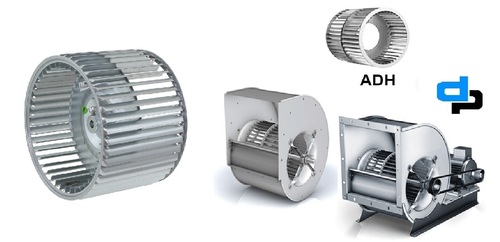

- Forward Curved Centrifugal Fan

- Material

- Galvanized Steel / Mild Steel

- Capacity

- Up to 37000 m/h

- Pressure

- Up to 720 Pa

- Application

- Ventilation, HVAC Systems, Industrial Air Movement

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 1440 RPM

- Noise Level

- <85 dB(A)

- Power Source

- Electric

- Voltage

- 415 V

- Weight

- 390 kg

- Dimension (L*W*H)

- 1560 x 1600 x 1540 mm (approx.)

- Color

- Silver / Metallic Grey

Nicotra Forward Curved Centrifugal Fan ADH 1400 X1 Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Andaman and Nicobar Islands, Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, South India, Central India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Gujarat, Andhra Pradesh, Kerala, Odisha, Chhattisgarh, All India

About Nicotra Forward Curved Centrifugal Fan ADH 1400 X1

Nicotra Forward Curved Centrifugal Fan ADH 1400 X1

Product: ADH 1400 X1

Superior Engineering for Demanding Applications

Designed for reliability and versatility, the Nicotra ADH 1400 X1 is ideal for industrial air movement, ventilation, and large-scale HVAC systems. Its galvanized steel construction and forward curved impeller deliver efficient performance and exceptional longevity under varying operational conditions.

Customizable Operation and Easy Maintenance

With a belt-driven mechanism, base-mounted setup, and advanced ball bearings, this fan offers flexibility in installation and straightforward servicing. Regular maintenance extends its lifespan beyond 10 years, making it a cost-effective choice for long-term ventilation solutions.

FAQs of Nicotra Forward Curved Centrifugal Fan ADH 1400 X1:

Q: How do I install the Nicotra ADH 1400 X1 centrifugal fan?

A: The fan is designed for base mounting, usually on a flat, stable surface near your ductwork. Ensure it is securely bolted, properly aligned, and all electrical connections are made by a qualified technician, following safety standards and local regulations.Q: What applications are best suited for this fan model?

A: This fan is ideal for ventilating industrial facilities, commercial HVAC systems, and any application requiring efficient air movement, such as manufacturing plants, warehouses, or large public spaces needing high airflow rates.Q: When is maintenance required and what does it involve?

A: Regular maintenance should be performed at intervals recommended by the manufacturer, generally every 6-12 months. Key tasks include checking belt tension, inspecting ball bearings, cleaning the impeller, and verifying the integrity of electrical connections.Q: Where should I position the fan for optimal airflow and safety?

A: Install the fan in a well-ventilated area away from direct heat sources and obstructions. Ensure theres enough clearance around the discharge and inlet sides for unobstructed airflow and allow easy access for routine inspection and maintenance.Q: What are the main benefits of the galvanized sheet steel impeller?

A: Galvanized sheet steel offers excellent durability and corrosion resistance, ensuring optimal performance even in challenging industrial environments, reducing the risk of downtime and maintenance costs.Q: How does the IP55 protection class benefit the system?

A: The IP55 protection ensures the fans motor and components are safeguarded against dust ingress and water jets, making the fan reliable for tough, dusty, or slightly damp environments.Q: What is the typical process for replacing the belts in the drive system?

A: To replace the belts, first disconnect the power supply, remove any protective guards, ease the belt tension, and replace worn belts with recommended sizes. After installation, adjust tension as per guidelines, rotate by hand to ensure alignment, then restore power and test the operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ADH Nicotra Forward Curved Centrifugal Fan Category

Nicotra Forward Curved Centrifugal Fan ADH 280 R

Price 21500.00 INR

Minimum Order Quantity : 1 Piece

Voltage : 230 V

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Product Type : Others, Forward Curved Centrifugal Fan

Nicotra Forward Curved Centrifugal Fan ADH 500 R

Price 41000.00 INR

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Product Type : Others, Forward Curved Centrifugal Fan

Nicotra Forward Curved Centrifugal Fan ADH 180 R

Price 15000 INR

Minimum Order Quantity : 2 Pieces

Voltage : 230 V

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Product Type : Others, Forward Curved Centrifugal Fan

Nicotra Forward Curved Centrifugal Fan ADH 560 R

Price 47000.00 INR

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Product Type : Others, Forward Curved Centrifugal Fan

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS