Dust Collector Pleated Cartridge Filter

Dust Collector Pleated Cartridge Filter Specification

- Efficiency (%)

- 99.99%

- Resistance

- Initial resistance at 20mm water column

- Capacity

- 1200-1500 CFM (cubic feet per minute)

- Diameter

- 150 mm - 325 mm

- Type

- Pleated Cartridge Filter

- Material

- Polyester non-woven fabric with or without PTFE coating

- Thickness

- 0.7 mm - 1.0 mm

- Thermal Shrinkage

- Less than 1% at 120C for 30 minutes

- Working Temperature

- Up to 120C

- Application

- Dust Collector Systems, Industrial Air Filtration

About Dust Collector Pleated Cartridge Filter

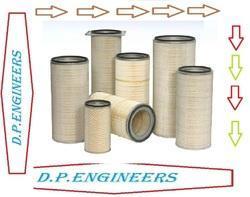

Dust Collector Pleated Cartridge Filter

We offer a number of Dust Collector Pleated Standard Filters that are available in three different diameters such as 150mm, 225mm and 325mm. These flanges are made from aluminum / stainless steel and its base and interior baskets are from 1.2mm galvanized steel.

Versatile Design and Construction

This pleated cartridge filter fits a range of industrial dust collector systems, thanks to adjustable dimensions and mounting options. Choose cylindrical, oval, or conical shapes to accommodate diverse applications and space constraints. The filters construction utilizes high-quality end caps (GI, SS, or PU) and stable inner cores, providing resistance against corrosion and structural deformation.

Enhanced Filtration Performance

Engineered for superior air filtration, the cartridge filter operates with 99.99% efficiency. Its filtration ratingsfrom 1 to 25 micronsaddress various particulate sizes, making it suitable for demanding environments. The use of polyester non-woven fabric with optional PTFE coating maximizes dust retention while maintaining minimal initial resistance and robust airflow, ensuring a cleaner workplace.

FAQs of Dust Collector Pleated Cartridge Filter:

Q: How does the pleated cartridge filter improve dust collector performance?

A: The pleated design offers a greater surface area (6 m to 20 m), enabling efficient air filtration with low initial resistance. This increases dust capture efficiency up to 99.99%, enhances airflow (1200-1500 CFM), and reduces maintenance frequency in industrial dust collector systems.Q: What materials are used for the end caps and inner core of the filter, and why are they important?

A: End caps are available in galvanized iron (GI), stainless steel (SS), or polyurethane (PU), and the inner core is made of GI or SS. These materials ensure chemical resistance, structural integrity, and compatibility with demanding industrial conditions, contributing to filter longevity and reliable performance.Q: When should the pleated cartridge filter be replaced in a dust collection system?

A: Filter replacement depends on the application, particle load, and pressure drop across the filter. Typically, when the initial resistance surpasses recommended levels or after prolonged operation in high dust environments, its advisable to replace the filter to maintain optimal system efficiency.Q: Where can these cartridge filters be installed within industrial facilities?

A: These filters are suitable for various dust collector systems across industriessuch as manufacturing plants, woodshops, metalworking units, and chemical processing facilitiesdue to their adaptable mounting (top, bottom, flange) and customizable size/shape options.Q: What is the process for installing this cartridge filter in a dust collector system?

A: Installation involves selecting the appropriate mounting style (top, bottom, or flange), ensuring a secure fit via polyurethane or rubber gasket sealing, and properly aligning the filter for optimal airflow. Always follow manufacturer recommendations for installation and handling to preserve filter integrity.Q: How does the filters material and construction benefit industrial air quality and safety?

A: With high-efficiency polyester non-woven fabric (optionally PTFE coated), the filter traps fine particulate matter ranging from 1 to 25 microns. Its thermal stability (up to 120C, minimal shrinkage) and robust build reduce airborne contaminants, safeguarding worker health and prolonging equipment life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dust Collector Filter Bag Category

Short Blast Filter Cartridges /Powder coating filters

Application : Cartridge Filter

Fiber Glass Pleated Panel Filter

Application : HVAC systems, clean rooms, pharmaceuticals, hospitals, electronics

Resistance : Low initial resistance

Type : Other, Panel filter, pleated

Working Temperature : Up to 80C

Material : Other, Fiber glass media, galvanized/Aluminum frame

Thermal Shrinkage : Less than 1% at 120C

Pocket Filter

Application : HVAC systems, industrial dust collection

Resistance : 45 Pa

Type : Other, Pocket Filter

Working Temperature : up to 80C

Material : Other, Synthetic fiber

Thermal Shrinkage : < 1.5%

Non Woven Filter Bags

Application : Industrial dust collection, HVAC, Liquid filtration, Pharma, Cement, Food

Resistance : Chemical and moisture resistant

Type : Other, Bag Filter

Working Temperature : Up to 120C

Material : Other, Non Woven Polypropylene / Polyester

Thermal Shrinkage : <1% at 120C

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS