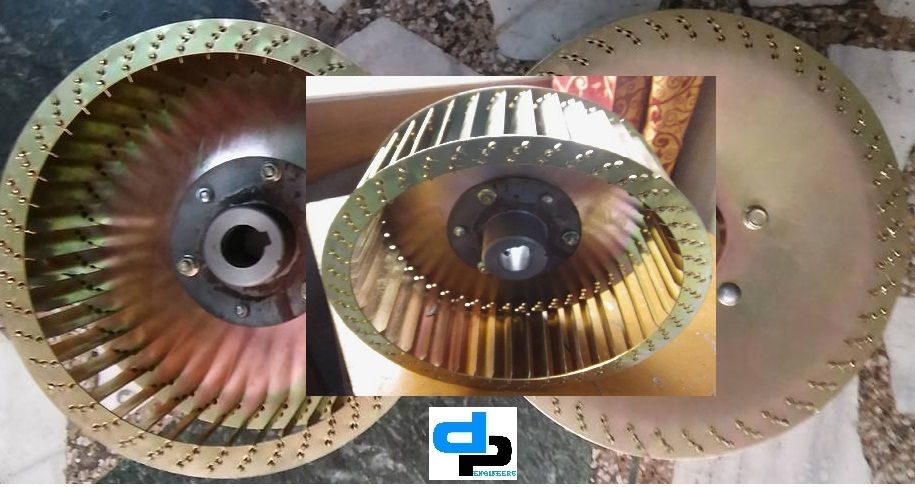

DIDW Centrifugal Fan 280 MM X 200 MM

DIDW Centrifugal Fan 280 MM X 200 MM Specification

- Power

- 0.5 kW

- Motor Power

- 0.5 kW

- Pressure Range

- 400 - 650 Pa

- Output Power

- 0.5 kW

- Max Pressure

- 650 Pa

- Flow Rate

- 500-700 CFM

- Life Span

- 10 Years

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Capacity

- 500-700 CFM

- Pressure

- 600 Pa

- Application

- Industrial Ventilation, Air Handling Units

- Frequency (MHz)

- 50 Hz

- Motor Speed

- 2900 RPM

- Noise Level

- 75 dB

- Power Source

- Electric

- Voltage

- 220-240 V

- Weight

- Approx. 15 kg

- Dimension (L*W*H)

- 280 mm x 200 mm

- Color

- Blue

DIDW Centrifugal Fan 280 MM X 200 MM Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Tripura, Manipur, All India, South India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Uttar Pradesh, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Pondicherry, Uttarakhand, Daman and Diu, Central India

About DIDW Centrifugal Fan 280 MM X 200 MM

DIDW Centrifugal Fan 280 MM X 200 MM

DIDW CENTRIFUGAL BLOWER

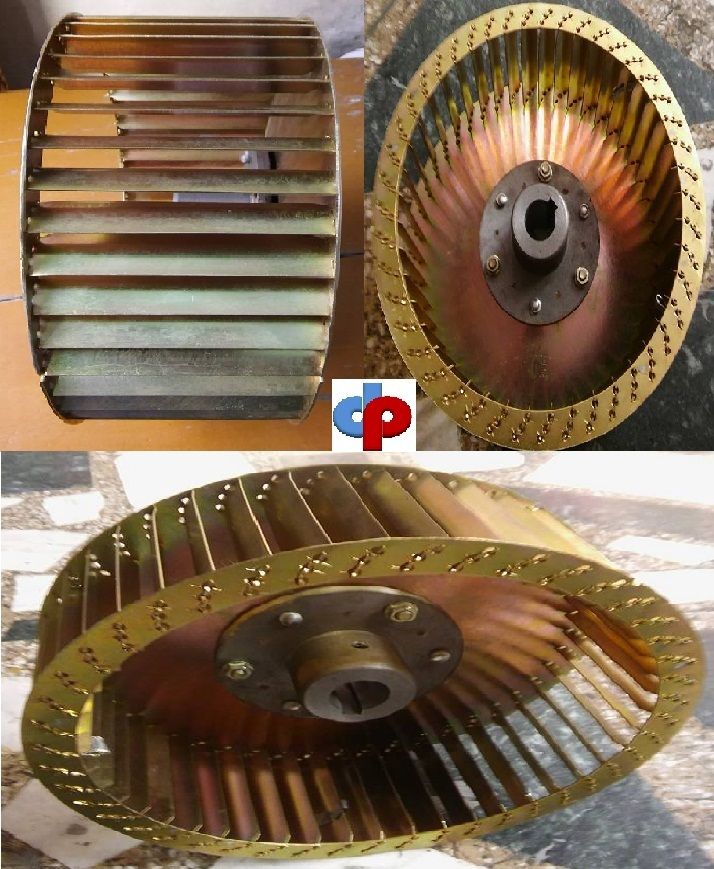

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 44 | DP 11 80 | 280 X 200X 229 | 11 X 8 | 12.70 (1/2) & 15 MM & 20 MM | AL. / GI. |

Engineered for Versatile Air Handling

Designed with industrial needs in mind, the DIDW Centrifugal Fan boasts both clockwise and counterclockwise rotation to adapt to varied installation configurations. Its backward curved impeller and TEFC enclosure combine efficiency and safety. Backed by an IP55 protection class, it withstands challenging operating conditions, making it ideal for ventilation systems in factories and air handling units.

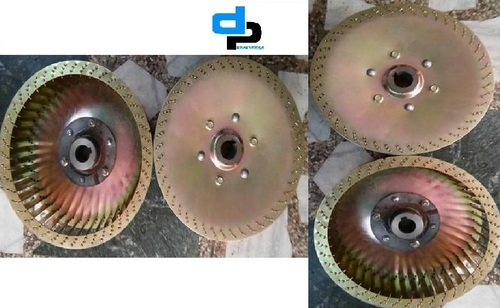

Outstanding Reliability and Performance

Operating within a temperature range of -20C to 60C and up to 95% relative humidity, this centrifugal fan offers a long service life up to 10 years. With a motor speed of 2900 RPM and direct drive configuration, it delivers consistent airflow and pressure, supporting capacities between 500 and 700 CFM while maintaining noise levels below 75 dB.

FAQs of DIDW Centrifugal Fan 280 MM X 200 MM:

Q: How can the DIDW Centrifugal Fan be installed for optimal performance?

A: The fan is designed for base mounting, allowing secure installation on flat surfaces. For optimal airflow and efficiency, ensure the correct orientation (clockwise or counterclockwise rotation) and follow the manufacturers guidelines for alignment and secure fitting.Q: What are the main applications of this centrifugal fan in industrial settings?

A: This fan is ideally suited for industrial ventilation systems and air handling units, where precise and reliable air movement is required to maintain air quality and temperature control.Q: When is maintenance recommended for the DIDW Centrifugal Fan?

A: Routine checks every six months are recommended, focusing on ball bearing lubrication, motor integrity, and enclosure cleanliness to ensure smooth operation and extended lifespan.Q: Where is the fan most effectively used in a facility?

A: It performs best in areas requiring consistent air exchange, such as production lines, workshops, and zones with high humidity, thanks to its robust design and TEFC enclosure.Q: What process ensures protection from environmental factors?

A: The totally enclosed fan cooled (TEFC) motor and IP55-rated enclosure protect the internal components from dust, moisture, and accidental contact, promoting longevity even in harsh conditions.Q: How does the backward curved impeller benefit airflow?

A: The backward curved impeller design increases static efficiency up to 65%, minimizes energy waste, and reduces noise during operation, delivering powerful yet quiet ventilation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Forward Curved Fan Category

DIDW Centrifugal Fan 330 MM X 250 MM

Price 7500 INR

Minimum Order Quantity : 5 Pieces

Voltage : 220415 V

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Industrial Ventilation, HVAC, Air Handling Units, Exhaust Systems

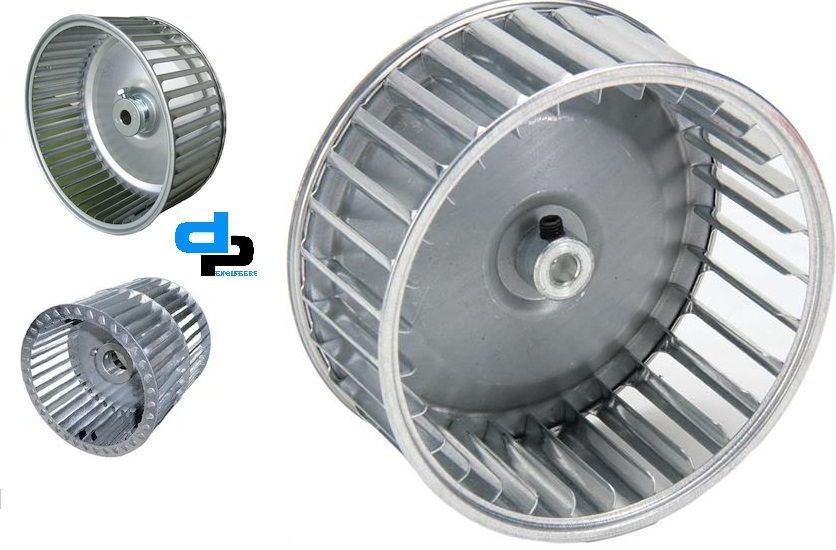

DIDW Centrifugal Fan 230 MM X 127 MM

Price 1500 INR

Minimum Order Quantity : 5 Pieces

Voltage : 230 V AC

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Air ventilation, HVAC, Industrial Exhaust

DIDW Centrifugal Fan 200 MM X 203 MM

Price 2000 INR

Minimum Order Quantity : 5 Pieces

Voltage : 230 V / 415 V

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, Ventilation, HVAC, Industrial Exhaust, Air Handling Units

DIDW Centrifugal Fan 610 MM X 610 MM

Price 25000.00 INR

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Power Source : Other, Electric

Frequency (MHz) : 50 Hz

Application : Other, HVAC, Ventilation, Air Handling Units, Industrial Exhaust

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS