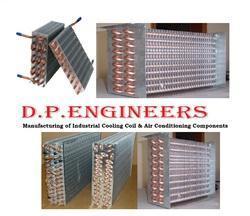

Condenser Coils

Condenser Coils Specification

- Surface Treatment

- Powder Coated

- Material

- Copper or Aluminum

- Technique

- Fin and Tube, Mechanically Bonded

- Grade

- Industrial Grade

- Coil Thickness

- 0.3 mm - 0.6 mm

- Coil Weight

- Customizable as per design

- Coil Length

- Up to 6 Meters (Customizable)

- Hardness

- Standard (Annealed/Tempered as required)

- Application

- HVAC, Refrigeration, Chilling Units

About Condenser Coils

Condenser Coils

We are manufactured using a high quality of raw materials which have been bought from reliable vendors and they are supplied and exported to the clients located across the globe. These coils are used for a range of applications in different products and they offer a high performance to the customers. These products have been priced at very reasonable rates and they offer a long lasting service life to the customers in the market.

Features:

- Effective

- High performance

- Cost effective

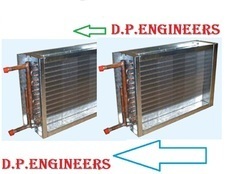

Condenser

| ||

| STANDARD SIZE | COPPER PIPE SIZE | |

| 18 X 16 X 4 ROW | 3/8 | |

| 14 X 14 X 4 ROW | 3/8 | |

| 13 X 12 X 4 ROW | 3/8 | |

| 13 X 12 X 3 ROW | 3/8 | |

| 10 X 12 X 3 ROW | 3/8 | |

CONDENSER COIL | ||

| Model No | STANDARD SIZE | COPPER PIPE SIZE |

| DP | 10 X 11 X 3 ROW | 3/8 |

| DP | 10 X 11 X 2 ROW | 3/8 |

| DP | 10 X 11 X 2 ROW | 3/8 |

| DP | 9 X 9 X 2 ROW | 3/8 |

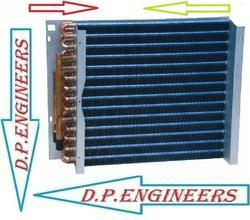

Versatile Design and Custom Solutions

Choose from various tube diameters, fin materials, and spacings to match your systems demands. Each condenser coil can be fully customized in size, material, coil length (up to 6 meters), and fittings, ensuring seamless integration into your application. Our engineering team works closely with clients to provide tailored solutions for HVAC and refrigeration projects.

Superior Durability and Corrosion Protection

Engineered for longevity, our coils feature an anti-corrosive, powder-coated finish and are made from industrial-grade copper or aluminum. Each unit is 100% pressure tested to ensure leak-free performance, making them suitable for challenging environments requiring maximum reliability and durability.

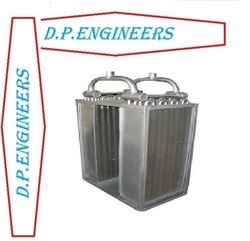

Efficiency and Ease of Installation

Our condenser coils offer high heat transfer efficiency, translating into optimized cooling or refrigeration performance. With options for either horizontal or vertical mounting, installation is straightforward and adaptable to different system layouts. Each coil is precisely manufactured for consistent performance and minimal maintenance.

FAQs of Condenser Coils:

Q: How are the condenser coils tested for quality and reliability?

A: Each condenser coil undergoes comprehensive 100% pressure leak testing to ensure they can withstand operating pressures of up to 450 PSI. This rigorous process guarantees durability and leak-free operation in demanding HVAC or refrigeration environments.Q: What options are available for customization of condenser coils?

A: We offer extensive customization for coil size, tube diameter, material (copper or aluminum), fin spacing, coil thickness, and fittings. Additionally, coil length can be tailored up to 6 meters and coil weight adjusted to meet specific design requirements.Q: Where can these condenser coils be installed?

A: Our condenser coils are suitable for a wide range of installations, including HVAC systems, commercial refrigeration, and industrial chiller units. They can be mounted either horizontally or vertically depending on your applications needs.Q: What is the benefit of the anti-corrosive finish and powder coating?

A: The anti-corrosive finish combined with powder coating enhances the coils resistance to harsh environmental factors, significantly prolonging its service life and reducing maintenance requirements, particularly in industrial and coastal applications.Q: How does the fin and tube mechanical bonding technique improve performance?

A: This advanced technique ensures optimal contact between the fins and tubes, maximizing heat transfer efficiency. The result is quicker and more effective cooling or heat exchange, leading to improved energy efficiency for your system.Q: When is it recommended to opt for copper versus aluminum material?

A: Copper coils are preferred for applications requiring exceptional thermal conductivity and durability, while aluminum offers a lighter, cost-effective alternative with good heat transfer performance. We help you select the ideal material based on your operational and budgetary needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cooling And Condenser Coils Category

Fan Coil Unit Cooling Coils

Warranty : 1 year manufacturer warranty

Technique : Other, Fin and Tube

Material : Copper and Aluminum, Other

Application : HVAC systems

Hardness : Standard

Coil Weight : Varies

Heat Exchanger Coils

Warranty : 1 Year

Technique : Other, High Precision Welding

Material : Other, Copper and Aluminum

Application : HVAC Systems

Hardness : Standard

Coil Weight : Varies with size

Laundry Tumbler Steam Radiators

Warranty : 1year manufacturer warranty

Technique : Other, Welded and engineered for optimized heat exchange

Material : Stainless Steel

Application : Laundry equipment for drying and steam heating

Hardness : Medium to High

Coil Weight : Depends on size approximately 2050 kg

Copper Cooling Coil

Warranty : 1 year

Technique : Other, Precision manufacturing

Material : Other, Copper

Application : HVAC systems

Hardness : Durable construction

Coil Weight : Varies by specification

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS